This blog is partly based on Dr Michael Heidings PhD theses, which can be downloaded online

Why do LED luminaires fail?

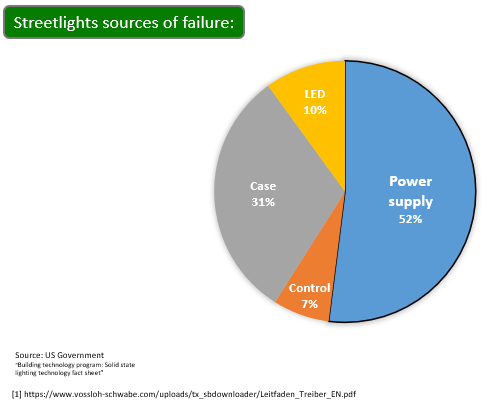

A study by the “Building Technology Office” from the US Government, shows that 52% of all LED streetlights failures are related to the power supply and only 10% are related to the LEDs themselves. The respective graphic is depicted in Figure 2. Therefore, a true long-life power supply is required to further increase luminary reliability

The lifetime of LEDs

An optimistic, nonstandard conforming, approximation for LEDs estimates 150’000 to 200’000 hours of a lifetime at a temperature of 65 degrees. (Additional Footnote: It depends on the exact LED used for reference. Oversimplified-speaking, a newer low power version will last longer.) This equals 23 years of continuous operation.

Thus, for commercial applications, LEDs may be replaced due to technical innovation instead of being replaced due to defects. In contrast to the 150’000 hours to 200’000 hours lifetime of LEDs, the driver service life ranges between 20’000 h and 50’000 h, meaning that a LED power supply has to be exchanged four to ten times before the LED module reaches its end of life. Therefore, the LED driver is typically constructed to be replaceable, not the LED module. To extend the service life of the LED luminaire, a long-lasting and efficient power supply is key.

What limits the lifetime of LED Luminaires?

Based on my experience, a lifetime is limited due to the following factors:

- FANs: Fans are susceptible to dust and reduce therefore are clogging air channels. Clogged air channels lead to increased temperature, resulting in accelerated ageing. A typical maintenance interval is required every 7’500 hours to 15’000 hours. The good news is, that most LED drivers do not require any fan.

- Electrolytic capacitors have a typical high-temperature lifetime (typical 70°C) of 30’000 to 50’000h. By adequate design with film capacitors, a lifetime of 200’000h are possible.

- MOSFETs and switches may be destroyed by overvoltage. For adequate design, stress parameters must be measured under high line operating conditions. A good manufacturer may offer these stress reports to their customer. (For sure, mostly you have to ask!).

- Overvoltage protection is a big issue especially LED street lighting. Therefore, adequate overvoltage protection must be in place.

Generally speaking, the typical high-volume manufacturers (I’m pretty sure there are some exceptions!) will not admit, that their technology has some natural limits. They will say, that it will just work. Internally they hope to make it over the refund period. That may work also for you if you provide discardable products as electric toothbrushes. However, if you are a supplier of long-lasting equipment (industrial, transportation, etc.) that saving may impact your brand.

Where do get long life power supplies?

Well, to be honest, it’s pretty hard. You are required to have a lot of experience to judge for yourself. We can discuss your ideas and requirements together.

From my point of view, we should take a step back from our disposable culture and invest in high-end long-life equipment. One approach is, which I’m an evangelist for, to construct long power supplies. If the power supply breaks, everything else breaks also for sure.